Present Location: Mold

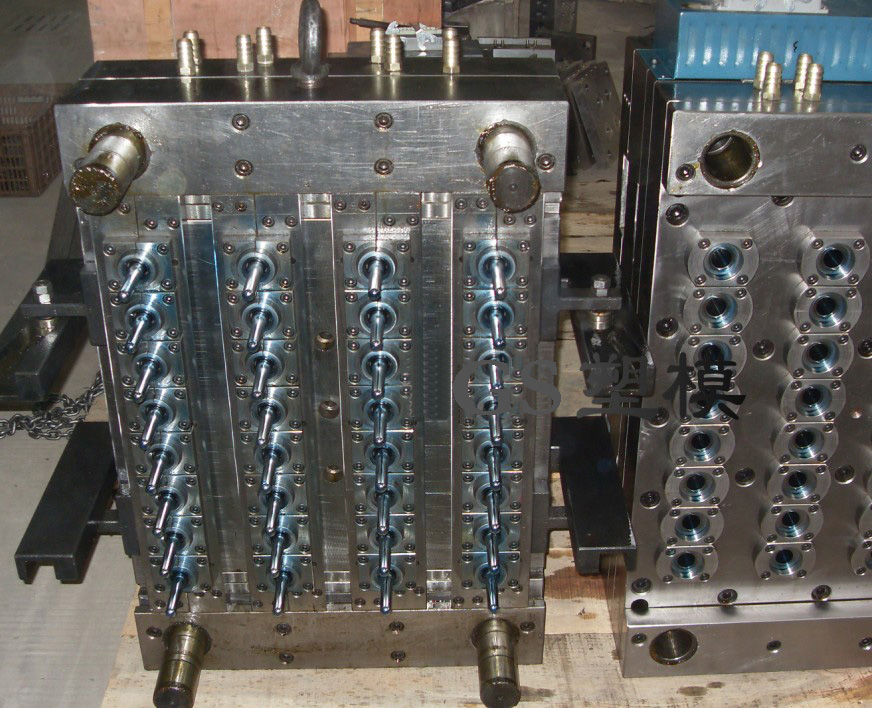

Name: 32 cavities Pin-valve hot runner mold

Category: Mold

Pin-valve Hot runner PET Preform mold

1) High technology design of the perform mould .All of the moulds are designed as international standard. .In dividual temperature controlling system adopted Japan Omron components. Off-center for each cavity of the perform mould to be sure less than 0.05mm.

2) Two directions hot runner design, the injection point for each perform is perfectly without any damage for the blowing of the bottle.

3) Each mold with 2 million shots guarantee.

Main features

◆ Off-center adjustment system

Off-center adjustment system can make the error of preform’s wall thickness less than 0.05mm. This system does not affect the lifetime of mould

◆ Self-lock System

International advanced bi-awls fixed orientation self-locked structure has been adopted

◆ Cooling System

On the preform mould’s each inner part,including core, cavity and valve gate system, there is all specially designed cooling system with perfect cooling effect and sbundant strength

◆ Heating System

Double heating system can ensure that the impact of heating is good and quality control is credible. The Heating Band unit makes nozzles be with invariable temperature. The Heater Unit is used to heat the hot runner plate with long using life and powerful haating capacity

◆ Hot Runner System

The preform mold adopts Pin-valve type Hot Runner System,such hot runner system can reduce mould’s each part’s wear&tera and maintenance cost,and also save 10%~15% electric energy

◆ Hydraulic Ejectiong System

The preform-doffing success ratio has achieved firm endurance and the whole preform ejecting process will become much quieter

Technical parameters for reference:

|

ITEM

|

HIGH(MM)

|

WIDTH(MM)

|

THICKESS(MM)

|

WEIGHT(KG)

|

|

4 cavity

|

345

|

350

|

436

|

310

|

|

6 cavity

|

410

|

410

|

480

|

390

|

|

8 cavity

|

475

|

410

|

480

|

450

|

|

12 cavity

|

605

|

410

|

480

|

570

|

|

16 cavity

|

750

|

410

|

480

|

650

|

|

24 cavity

|

785

|

500

|

520

|

1100

|

|

32 cavity

|

860

|

600

|

520

|

1400

|

|

48 cavity

|

1120

|

645

|

580

|

1750

|

|

72 cavity

|

1080

|

800

|

580

|

2500

|

Features of Cap mold

◆ Mold ranges from 1 cavity to 72 cavities

◆ The mold plate is made of stainless steel.

◆ Standard interchangeable mold components

◆ Special designed nozzles ensure our unique feature

◆ High performance hot runner system ensures uniform melt flow and pressure in all cavities

◆ All of parts are manufactured by CNC equipments

Every perfect PET bottle accordingly has a suitable plastic cap while a proper cap makes bottles better. We offer high quality hot runner and cold runner cap injection mold up to 72 cavities to help you produce an ideal plastic cap. From our products list you will find various moulds to produce normal screw cap, tamper-proof cap, flip-top cap and so on, which cover the package market of mineral water, soft drinks, juice, as well as some other food and non-food package

Features of blowing mold

◆ The mold is made by high quality steel

◆ The mold is designed with 3D modeling software

◆ Reliable hard chrome plated

◆ Various container designs for option

◆ Proper cooling channel design and leakage proof

◆ All of the parts are manufactured with CNC equipments